2015 quality and cheap ndfeb products

Product Description

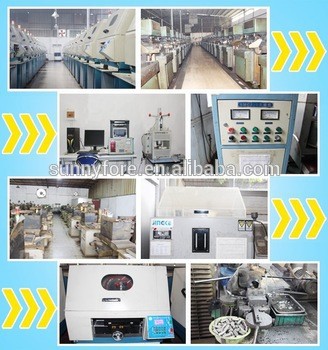

Sunny Fore magnet Co.,Ltd established in 1997,Located in the west of Guangdong Province in China, the Pearl River Delta emerging manufacturing base in Jiangmen City Xinhui Ma Chong Industrial zone.Sunny Fore is a company specializing in the production of sintered neodymium iron boron Permanent Magnet.Our leading products are sintered neodymium iron boron permanent magnet,bonded neodymium iron boron permanent magnet, rubber ferrite permanent magnet etc.Widely used in toys, hardware, electronics, electro acoustic instruments, medical technology and other devices and equipment in permanent magnet.Sunny Fore magnet Co. Ltd has advanced production equipment and testing equipment, has a strong R & D and technical team.Successfully passed ISO9001-2008 quality system certification and ISO14001:2004 environmental management system certification. Company product image:  Company equipment picture:

Company equipment picture:  Magnet performance table:

Magnet performance table:  Physical properties:

Physical properties:  Magnetic energy parameters and conversion table:

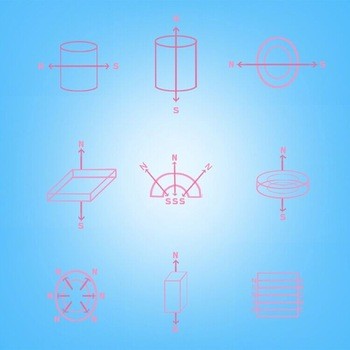

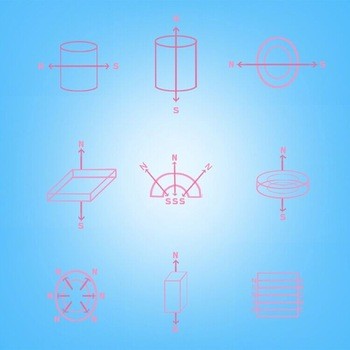

Magnetic energy parameters and conversion table:  Magnetizing direction:

Magnetizing direction:  Note: 1, temperature Neodymium iron boron is a powerful magnet, high price, with good mechanical properties, but low Curie temperature, temperature characteristics, higher than 80 DEG C will lead to degaussing. 2, environment Neodymium iron boron strong magnet suitable for storage in dry and ventilated room, acidic, alkaline, organic solvent, water, hot and humid environment easy to make magnet rust, coating shedding of powdered magnet demagnetization. The main reason for plating products should be paid more attention to, when stored properly oiled to prevent rust. This is why we advised neodymium iron boron magnet surface anti-corrosion treatment. Such as: blue and white zinc plating, double layer nickel, nickel copper, nickel, nickel, electroless nickel, epoxy resin, etc.. 3, stacking and handling Neodymium iron boron magnetic materials, hard, brittle, strong magnetic field to handle with care (especially large size and thin), when a strong magnet by itself or with other iron attraction or separation, to be careful not shock. Otherwise easy to cause damage to the cause of the collision and the magnet or clip. Because the neodymium iron boron belongs to the multi metal alloy material, the density is 7.45, has the weight and the brittle characteristic. So be very careful in handling the move, so as not to magnetic. Storage should also keep the environment dry, do not directly stacked on the ground, the best pad on the board or placed on the shelf. Surface treatment index:

Note: 1, temperature Neodymium iron boron is a powerful magnet, high price, with good mechanical properties, but low Curie temperature, temperature characteristics, higher than 80 DEG C will lead to degaussing. 2, environment Neodymium iron boron strong magnet suitable for storage in dry and ventilated room, acidic, alkaline, organic solvent, water, hot and humid environment easy to make magnet rust, coating shedding of powdered magnet demagnetization. The main reason for plating products should be paid more attention to, when stored properly oiled to prevent rust. This is why we advised neodymium iron boron magnet surface anti-corrosion treatment. Such as: blue and white zinc plating, double layer nickel, nickel copper, nickel, nickel, electroless nickel, epoxy resin, etc.. 3, stacking and handling Neodymium iron boron magnetic materials, hard, brittle, strong magnetic field to handle with care (especially large size and thin), when a strong magnet by itself or with other iron attraction or separation, to be careful not shock. Otherwise easy to cause damage to the cause of the collision and the magnet or clip. Because the neodymium iron boron belongs to the multi metal alloy material, the density is 7.45, has the weight and the brittle characteristic. So be very careful in handling the move, so as not to magnetic. Storage should also keep the environment dry, do not directly stacked on the ground, the best pad on the board or placed on the shelf. Surface treatment index:  Technological process: 1, the raw materials in accordance with Nd2Fe14B ingredients. 2, the configuration of the raw materials of the present invention into the vacuum melting furnace (or swing furnace), high temperature melting, forming alloy ingot (or rejection). 3, the alloy ingot (or rejection) after breaking into hydrogen, the jet mill, only a few micron sized particles. 4, the magnetic field in the actual demand for magnetic powder pressing molding. 5, forming the material after the high temperature of 1000 degrees above the vacuum sintering, and then in the aging process to achieve the corresponding magnetic properties. 6, magnetic energy testing. 7, according to the requirements of the size and shape of mechanical processing and surface treatment. 8, appearance inspection. Process flow chart:

Technological process: 1, the raw materials in accordance with Nd2Fe14B ingredients. 2, the configuration of the raw materials of the present invention into the vacuum melting furnace (or swing furnace), high temperature melting, forming alloy ingot (or rejection). 3, the alloy ingot (or rejection) after breaking into hydrogen, the jet mill, only a few micron sized particles. 4, the magnetic field in the actual demand for magnetic powder pressing molding. 5, forming the material after the high temperature of 1000 degrees above the vacuum sintering, and then in the aging process to achieve the corresponding magnetic properties. 6, magnetic energy testing. 7, according to the requirements of the size and shape of mechanical processing and surface treatment. 8, appearance inspection. Process flow chart:  How to buy high temperature magnets? One, at the working temperature of 80 degrees --230 degrees between the choice of high temperature magnets, the specific grade is as follows: 1, at 80 degrees --100 degrees between the working temperature of can choose M file of Ndfeb Magnet high temperature 2, can choose H file of NdFeB magnets in the high temperature of 100 degrees --120 degrees between the working temperature of 3, can choose SH file of NdFeB magnets in the high temperature of 120 degrees --150 degrees between the working temperature of 4, can choose UH file of NdFeB magnets in the high temperature of 150 degrees --180 degrees between the working temperature of 5, can choose EH file of NdFeB magnets in the high temperature of 180 degrees --200 degrees between the working temperature of 6, can choose AH file of NdFeB magnets in the high temperature of 200 degrees --230 degrees between the working temperature of Company certificate:

How to buy high temperature magnets? One, at the working temperature of 80 degrees --230 degrees between the choice of high temperature magnets, the specific grade is as follows: 1, at 80 degrees --100 degrees between the working temperature of can choose M file of Ndfeb Magnet high temperature 2, can choose H file of NdFeB magnets in the high temperature of 100 degrees --120 degrees between the working temperature of 3, can choose SH file of NdFeB magnets in the high temperature of 120 degrees --150 degrees between the working temperature of 4, can choose UH file of NdFeB magnets in the high temperature of 150 degrees --180 degrees between the working temperature of 5, can choose EH file of NdFeB magnets in the high temperature of 180 degrees --200 degrees between the working temperature of 6, can choose AH file of NdFeB magnets in the high temperature of 200 degrees --230 degrees between the working temperature of Company certificate:  To enable us to work more effectively with your work and save time, we need you to provide the following information: 1 what material, performance? 2 dimensions and tolerances? 3 is to to magnetization, magnetization? What way, axial? Radial? The maximum temperature of 4 magnet working environment? 5 order quantity? 6 surface treatment? Galvanized, nickel? 7 for special treatment, please inform. According to our latest experience, the most effective way to order the magnet, can save you time! If you are looking for a Magnet Products with high quality, reasonable price, punctual delivery and professional magnetic applied technology support. FAQ 1:How long will you give me the reply? we will contact you in 12 hours as soon as we can. 2:Could I get samples? Yes,we have materials in stock to help you to get the samples as soon as we can. 3:How about the quality of the magnets? We buy quality raw material processing, in line with international standards 4:How is the price? As we believe the quality is the most important,we will provide the best quality magnet we can with reasonable price. 5:Could you provide me the shortest lead time? We have materials in our stock,if you really need,you can tell us and we will try our best to satisfy you. 6:Could I visit your factory? Of course,if you need we will help you to visit our factory. 7:If I have paid,when will you help me to produce? When we have received the money in our account,we will give you the receipt and arrange to produce immediately. Contact us if you need more details on Type of Powerful Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Type Ndfeb Strong Magnet、Tile Type Neodymium Magnets. If these products fail to match your need, please contact us and we would like to provide relevant information.

To enable us to work more effectively with your work and save time, we need you to provide the following information: 1 what material, performance? 2 dimensions and tolerances? 3 is to to magnetization, magnetization? What way, axial? Radial? The maximum temperature of 4 magnet working environment? 5 order quantity? 6 surface treatment? Galvanized, nickel? 7 for special treatment, please inform. According to our latest experience, the most effective way to order the magnet, can save you time! If you are looking for a Magnet Products with high quality, reasonable price, punctual delivery and professional magnetic applied technology support. FAQ 1:How long will you give me the reply? we will contact you in 12 hours as soon as we can. 2:Could I get samples? Yes,we have materials in stock to help you to get the samples as soon as we can. 3:How about the quality of the magnets? We buy quality raw material processing, in line with international standards 4:How is the price? As we believe the quality is the most important,we will provide the best quality magnet we can with reasonable price. 5:Could you provide me the shortest lead time? We have materials in our stock,if you really need,you can tell us and we will try our best to satisfy you. 6:Could I visit your factory? Of course,if you need we will help you to visit our factory. 7:If I have paid,when will you help me to produce? When we have received the money in our account,we will give you the receipt and arrange to produce immediately. Contact us if you need more details on Type of Powerful Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Type Ndfeb Strong Magnet、Tile Type Neodymium Magnets. If these products fail to match your need, please contact us and we would like to provide relevant information.

Company equipment picture:

Company equipment picture:  Magnet performance table:

Magnet performance table:  Physical properties:

Physical properties:  Magnetic energy parameters and conversion table:

Magnetic energy parameters and conversion table:  Magnetizing direction:

Magnetizing direction:  Note: 1, temperature Neodymium iron boron is a powerful magnet, high price, with good mechanical properties, but low Curie temperature, temperature characteristics, higher than 80 DEG C will lead to degaussing. 2, environment Neodymium iron boron strong magnet suitable for storage in dry and ventilated room, acidic, alkaline, organic solvent, water, hot and humid environment easy to make magnet rust, coating shedding of powdered magnet demagnetization. The main reason for plating products should be paid more attention to, when stored properly oiled to prevent rust. This is why we advised neodymium iron boron magnet surface anti-corrosion treatment. Such as: blue and white zinc plating, double layer nickel, nickel copper, nickel, nickel, electroless nickel, epoxy resin, etc.. 3, stacking and handling Neodymium iron boron magnetic materials, hard, brittle, strong magnetic field to handle with care (especially large size and thin), when a strong magnet by itself or with other iron attraction or separation, to be careful not shock. Otherwise easy to cause damage to the cause of the collision and the magnet or clip. Because the neodymium iron boron belongs to the multi metal alloy material, the density is 7.45, has the weight and the brittle characteristic. So be very careful in handling the move, so as not to magnetic. Storage should also keep the environment dry, do not directly stacked on the ground, the best pad on the board or placed on the shelf. Surface treatment index:

Note: 1, temperature Neodymium iron boron is a powerful magnet, high price, with good mechanical properties, but low Curie temperature, temperature characteristics, higher than 80 DEG C will lead to degaussing. 2, environment Neodymium iron boron strong magnet suitable for storage in dry and ventilated room, acidic, alkaline, organic solvent, water, hot and humid environment easy to make magnet rust, coating shedding of powdered magnet demagnetization. The main reason for plating products should be paid more attention to, when stored properly oiled to prevent rust. This is why we advised neodymium iron boron magnet surface anti-corrosion treatment. Such as: blue and white zinc plating, double layer nickel, nickel copper, nickel, nickel, electroless nickel, epoxy resin, etc.. 3, stacking and handling Neodymium iron boron magnetic materials, hard, brittle, strong magnetic field to handle with care (especially large size and thin), when a strong magnet by itself or with other iron attraction or separation, to be careful not shock. Otherwise easy to cause damage to the cause of the collision and the magnet or clip. Because the neodymium iron boron belongs to the multi metal alloy material, the density is 7.45, has the weight and the brittle characteristic. So be very careful in handling the move, so as not to magnetic. Storage should also keep the environment dry, do not directly stacked on the ground, the best pad on the board or placed on the shelf. Surface treatment index:  Technological process: 1, the raw materials in accordance with Nd2Fe14B ingredients. 2, the configuration of the raw materials of the present invention into the vacuum melting furnace (or swing furnace), high temperature melting, forming alloy ingot (or rejection). 3, the alloy ingot (or rejection) after breaking into hydrogen, the jet mill, only a few micron sized particles. 4, the magnetic field in the actual demand for magnetic powder pressing molding. 5, forming the material after the high temperature of 1000 degrees above the vacuum sintering, and then in the aging process to achieve the corresponding magnetic properties. 6, magnetic energy testing. 7, according to the requirements of the size and shape of mechanical processing and surface treatment. 8, appearance inspection. Process flow chart:

Technological process: 1, the raw materials in accordance with Nd2Fe14B ingredients. 2, the configuration of the raw materials of the present invention into the vacuum melting furnace (or swing furnace), high temperature melting, forming alloy ingot (or rejection). 3, the alloy ingot (or rejection) after breaking into hydrogen, the jet mill, only a few micron sized particles. 4, the magnetic field in the actual demand for magnetic powder pressing molding. 5, forming the material after the high temperature of 1000 degrees above the vacuum sintering, and then in the aging process to achieve the corresponding magnetic properties. 6, magnetic energy testing. 7, according to the requirements of the size and shape of mechanical processing and surface treatment. 8, appearance inspection. Process flow chart:  How to buy high temperature magnets? One, at the working temperature of 80 degrees --230 degrees between the choice of high temperature magnets, the specific grade is as follows: 1, at 80 degrees --100 degrees between the working temperature of can choose M file of Ndfeb Magnet high temperature 2, can choose H file of NdFeB magnets in the high temperature of 100 degrees --120 degrees between the working temperature of 3, can choose SH file of NdFeB magnets in the high temperature of 120 degrees --150 degrees between the working temperature of 4, can choose UH file of NdFeB magnets in the high temperature of 150 degrees --180 degrees between the working temperature of 5, can choose EH file of NdFeB magnets in the high temperature of 180 degrees --200 degrees between the working temperature of 6, can choose AH file of NdFeB magnets in the high temperature of 200 degrees --230 degrees between the working temperature of Company certificate:

How to buy high temperature magnets? One, at the working temperature of 80 degrees --230 degrees between the choice of high temperature magnets, the specific grade is as follows: 1, at 80 degrees --100 degrees between the working temperature of can choose M file of Ndfeb Magnet high temperature 2, can choose H file of NdFeB magnets in the high temperature of 100 degrees --120 degrees between the working temperature of 3, can choose SH file of NdFeB magnets in the high temperature of 120 degrees --150 degrees between the working temperature of 4, can choose UH file of NdFeB magnets in the high temperature of 150 degrees --180 degrees between the working temperature of 5, can choose EH file of NdFeB magnets in the high temperature of 180 degrees --200 degrees between the working temperature of 6, can choose AH file of NdFeB magnets in the high temperature of 200 degrees --230 degrees between the working temperature of Company certificate:  To enable us to work more effectively with your work and save time, we need you to provide the following information: 1 what material, performance? 2 dimensions and tolerances? 3 is to to magnetization, magnetization? What way, axial? Radial? The maximum temperature of 4 magnet working environment? 5 order quantity? 6 surface treatment? Galvanized, nickel? 7 for special treatment, please inform. According to our latest experience, the most effective way to order the magnet, can save you time! If you are looking for a Magnet Products with high quality, reasonable price, punctual delivery and professional magnetic applied technology support. FAQ 1:How long will you give me the reply? we will contact you in 12 hours as soon as we can. 2:Could I get samples? Yes,we have materials in stock to help you to get the samples as soon as we can. 3:How about the quality of the magnets? We buy quality raw material processing, in line with international standards 4:How is the price? As we believe the quality is the most important,we will provide the best quality magnet we can with reasonable price. 5:Could you provide me the shortest lead time? We have materials in our stock,if you really need,you can tell us and we will try our best to satisfy you. 6:Could I visit your factory? Of course,if you need we will help you to visit our factory. 7:If I have paid,when will you help me to produce? When we have received the money in our account,we will give you the receipt and arrange to produce immediately. Contact us if you need more details on Type of Powerful Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Type Ndfeb Strong Magnet、Tile Type Neodymium Magnets. If these products fail to match your need, please contact us and we would like to provide relevant information.

To enable us to work more effectively with your work and save time, we need you to provide the following information: 1 what material, performance? 2 dimensions and tolerances? 3 is to to magnetization, magnetization? What way, axial? Radial? The maximum temperature of 4 magnet working environment? 5 order quantity? 6 surface treatment? Galvanized, nickel? 7 for special treatment, please inform. According to our latest experience, the most effective way to order the magnet, can save you time! If you are looking for a Magnet Products with high quality, reasonable price, punctual delivery and professional magnetic applied technology support. FAQ 1:How long will you give me the reply? we will contact you in 12 hours as soon as we can. 2:Could I get samples? Yes,we have materials in stock to help you to get the samples as soon as we can. 3:How about the quality of the magnets? We buy quality raw material processing, in line with international standards 4:How is the price? As we believe the quality is the most important,we will provide the best quality magnet we can with reasonable price. 5:Could you provide me the shortest lead time? We have materials in our stock,if you really need,you can tell us and we will try our best to satisfy you. 6:Could I visit your factory? Of course,if you need we will help you to visit our factory. 7:If I have paid,when will you help me to produce? When we have received the money in our account,we will give you the receipt and arrange to produce immediately. Contact us if you need more details on Type of Powerful Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Type Ndfeb Strong Magnet、Tile Type Neodymium Magnets. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Other Magnet

Other Products

Hot Products

step shape gray epoxy special shape magnet motorblock 3m adhesive magnetD10*0.6mm thinner disc shape NdFeB magnetD25x4mm n42 round copper plating magnetround black epoxy magnetnickel plated neodymium magnet motorn35/n38/n40/n42/n45/n48/n50/n52 magnetjiangmen top sale zinc coated neodymium magnetfactory make magnet guangzhou customname badge magnet manufacturers chinacountersunk hole permanent magnet magnetic n42guangdong factory price buy nickel magnetN40 big arc shape powerful neo motor magnetstrong counter neodymium permanent magnetaxial magnetization ndfeb round magnets with holesring neodymium permanent magnet China factory price